In the era of Fourth Industrial Revolution, the fields of data science and analytics are not only growing by leaps and bounds but are also playing a vital part in driving the same.

In our previous article we talked about how Predictive Analytics and Industry 4.0 goes hand in hand when it comes to an organisational transformation. The link for the same is https://www.linkedin.com/pulse/industry-40-data-science-predictive-analytics-swapnil-kamalakar/

Let us now talk about how Fault prediction analytics and preventive maintenance analytics plays an important role in the era of Industry 4.0

It has been recently seen that organisations are focusing on data science and analytics as the tools for incremental gain throughout the business in lined to various business goals. But unfortunately they are unable to unlock the new values, data driven forecasts and outcomes from the same.

Fault prediction and preventive maintenance analytics along with cloud computing is amongst the most talked trend in automation in the manufacturing industry leading to boost the Industry 4.0 transformation. The fear of breakdown is nothing less than a nightmare for any manufacturing company, which involves huge costs, resources, time and efforts. The preventive maintenance techniques are framed in such a way that predicting the maintenance of a certain operational process becomes very easy. The key for this remains “right information and data at the right time for decision making”

Fault Prediction analytics and preventive maintenance analytics gives the domain experts a framework for designing a predictive maintenance solution / logic. The most common uses cases for the same can be termed as below;

a. Will this particular equipment in this particular operation process, fail? And When?

b. Determining the Life cycle of the equipment / tool or a part

c. Is there any deviation in the equipment / or its operational behaviour?

d. How can the equipment settings be optimised?

e. …and likewise.

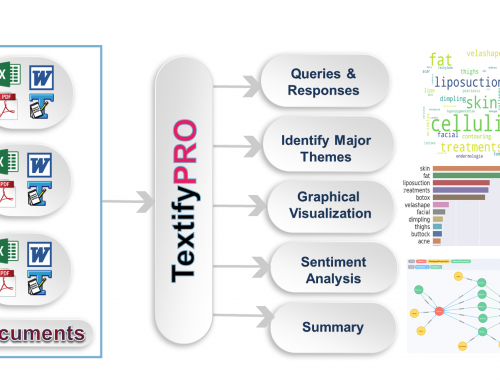

One of the classic challenges faced is managing a huge amount of data (from multiple sources which is cleaned / blended) to get deep actionable insights for taking data driven decisions. Hence despite having a great ERP tool, domain experts are not able to analyse the root cause of a certain operational problem on a real time basis. This leads to the necessity of a smart analytical platform which performs all the data blending processes necessary to give the desired outcomes for a predictive maintenance analytics.

Business Benefits of Analytics:

-

- Can let you save huge costs whether these are involved in resources, processes or time bound project scenarios.

- Helps you to save a lot a of productive time

- Helps you to analyse the operations and availability of the resources

- Determining the equipment lifespan and an efficient project lifecycle.

Hence, it becomes necessary for any manufacturing organisation to transform itself in line to a data driven decision making approach in this era of Industry 4.0

How are you leveraging Analytics in your company?

Talk to me at swapnil.k@alpha-analytics.com for a quick PoC for your use case, to find out an optimum solution.

Shall discuss about how analytics is a vital tool in Demand forecasting and Inventory Management, in the next article. Happy reading!